Aerial of North Central Plywood.

Knights of Columbus refreshment truck in the parking lot of North Central Plywood.

"Fun Days" visitors waiting in North Central Plywood parking lot to board helicopter for a ride.

"Fun Days" visitors boarding helicopter for a ride.

Northwood exhibit panel featuring a map of TFL 30 1993 five year plan.

Visitors inside the Northwood exhibit tent.

Northwood exhibit tents and Knights of Columbus refreshment truck in the parking lot of North Central Plywood.

Log decks at North Central Plywood.

Children going on pony rides around the North Central Plywood lot.

Helicopter flying over log decks towards North Central Plywood parking lot.

Northwood exhibit panel featuring the principles of sustainable forestry.

North Central Plywood work crew group photo taken outside on a winter's day, beehive burner visible in background.

North Central Plywood work crew group photo taken outside on a winter's day, beehive burner visible in background.

Group photo of work crew taken inside North Central Plywood.

Statistician, Bruno Rositano, beside computer panel of new knife carriage drive system at North Central Plywood.

Beehive burner at North Central Plywood.

Hauling short logs at North Central Plywood.

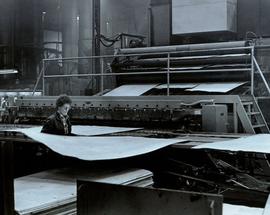

North Central Plywood sheets coming off belt drive.

Unidentified employee filing a piece of piping in a workshop.

Aerial perspective of North Central Plywood.

Unidentified crewman operating cutting saws at North Central Plywood.

Aerial of North Central Plywood.

Hydraulic feed system at North Central Plywood.

Forklift stacking finished and wrapped lumber onto railway cars.

Unidentified female employee filing holes in plywood sheeting.

Unidentified employee working at the spray box used for soaking wood with chemicals to alleviate fungus growth.

Group photo taken at lumber grading awards (L-R): Ron Reiter (Manager, NCP), unknown, unknown, Joe Ferreira, Harry Miller, Leonard Bourassa, Horace Ferreira, and Barry Brown.

Unidentified sawmill employee leaning against a shop table.

Plywood sheeting running along a conveyor belt.

Aerial photo of a Northwood sawmill.

Unidentified female employee stacking veneer before gluing.

Three NCP crewman working with plywood sheeting next to a helium neon laser.

Group shot of tradesmen who invented a new veneer stacker from scrap metal. (L-R) Pete Dancey, Torben Lindstrom, Ron Wanner, Gary Schleshinger, Ernie Dougan, John Bidner, Ron Empey, and Neil Andrews.

Front end loader moving eight foot logs from coinditioning chest to in-feed, where logs will be peeled into veneer.

Lathe peeling a log into veneer.

Lathe peeling a log into veneer.

Sheet of veneer going into the cutter.

Glue being applied to sheets of veneer in strips.

Layering of veneers with glue.

Electrical board in the plant.

Veneer being cut and stacked on the lay-up line.

Unidentified female employee filling in imperfections on the plywood before it is stacked.

Unidentified employee monitoring the stacking of the veneer.

Debarked log on a lathe and about to be peeled into veneer.

Debarked log on a lathe and about to be peeled into veneer.

Debarked log on a lathe and about to be peeled into veneer.

Debarked log being peeled on a lathe.