Attached description: Workmen place last steel plates of Kamyr continuous digester - one of two which now feed the Skeena Kraft mill.

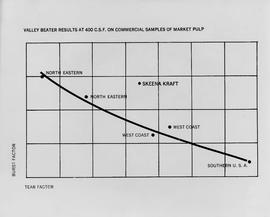

Attached description: The graph indicates how Skeena Kraft pulping characteristics compare with the burst-tear properties of other bleached kraft market pulps. In this relationship, Skeena Kraft develops the high bursting strength typical of northern Canadian krafts while retaining a distinct advantage in tearing strength.

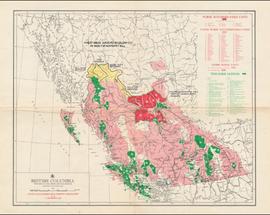

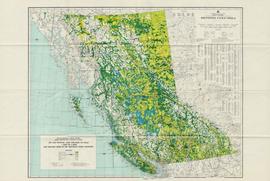

Item is a map of British Columbia's Status of Sustained-Yield Forestry Programme as at 31 December 1962. The map has been annotated to show forest area surveyed by Celgar Ltd. as base for new kraft mill.

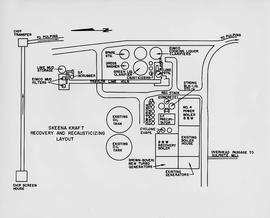

Item is a diagram of the layout of Skeena Kraft recovery and recausticizing.

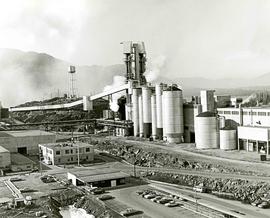

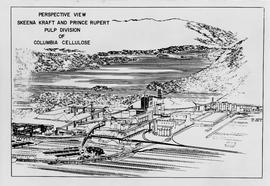

Attached description: The Skeena Kraft Group occupies the center of this picture showing the bleaching towers and the continuous Kamyr digesters. In the foreground is the Administration building, the Personnel and Safety building, and the employees' parking lot. The covered conveyor leading to the digesters carries chips. An emergency 1,000,000 water tower stands on the hill in the background.

Attached description: In early stages of construction Skeena Kraft mill was a beehive of activity as carpenters, steel workers, welders and many other trades project to completion.

Attached description: Brilliant lights outline the 750 t/d Skeena Kraft mill at night. Lights on the two Kamyr continuous digesters give the vessels the appearance of missiles in position for takeoff. Lights outline graphically the shape of the spacious and bright structure housing the pulping group, the pulp machine including wet-end equipment and Flakt Drier, and the large warehouse which is nearest the camera.

File consists of a folder containing documents describing Skeena Kraft Limited. Folder consists of:

- Svenska Cellulosa Aktiebolaget--A Forest Products Giant

- Columbia Cellulose Company, Limited--A Corporate History

- Two World-Wide Sales Organizations to Market Skeena Kraft Pulp

- Skeena Kraft Limited Adopts Distinctive Housemark Symbol Adapted from Sun Totem, Kee-War-Kow, Family Crest of Sky People

- The Nass and Skeena Valleys--A New Economic Region Terrace and Prince Rupert are Hubs in Finance and Services

- MISSING: Twinriver Timber Limited: New Company Created to Administer Two Tree Farm Licence Areas

- The Forests Behind the Coast Range Produce Superior Pulp

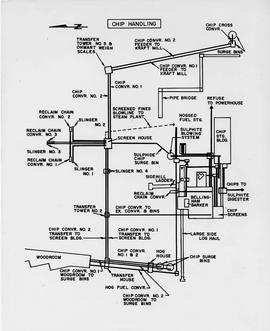

- Efficient New Woodroom Highlights Skeena Mill

- Integrating Two Power Systems--A Marriage with Convenience One Power Group Serves Two Mills

- Pulping Group Features Flexible Bleaching Sequence and World's Largest Flakt Drier

- New Dams Create Huge Storage Area for Skeena Water Supply

- Advanced Process Control Techniques Employ Computers Extensively

- Skeena Kraft Mill Quality Control and Process Control Tune Mill to Produce Prime Quality Pulps

- Co-ordination and Administration of Construction and Design of Skeena Kraft Shared by H.A. Simons and Central Engineering of Columbia Cellulose

- Purchasing and Traffic Departments Buy and Move More than 25,000 Tons of Materials During Skeena Kraft Construction Co-ordinated Sea and Land Transport System Introduced

- Skeena Kraft--Hundreds of New Jobs Canada-Wide Recruiting Programme Attracts New Workers to Growing Nass-Skeena Region;

- Also includes 19 photographs; 12 technical drawings and diagrams; 2 maps;

- Promotional pamphlet "The Skeena Kraft Story."

Attached description: Sample bales of Skeena Kraft bleached pulp are displayed by a receptionist, Jan Thompson, in front of a large aerial picture of the combined operations of the Columbia Cellulose sulphite mill and the Skeena Kraft mill at Prince Rupert. Sample bales are used to ship pulp to prospective customers who wish to test this new product, which, is already gaining recognition in world markets at a high quality pulp.

Attached description: A mile-long shear boom on the Nass River is used to guide single logs into holding ponds where they await bundling, booming and towing to mills. Boom is cleared of debris daily by river crew.

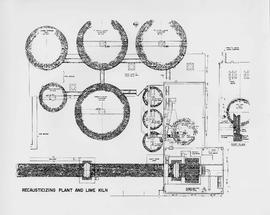

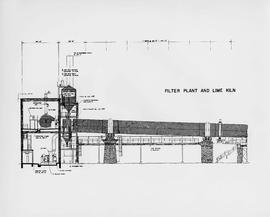

Item is a diagram of recausticizing plant and lime kiln.

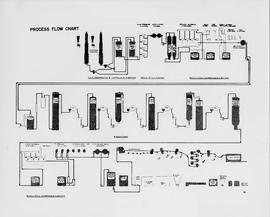

Item is a diagram showing the process through chip preparation and continuous digesting, brown stock washing, brown stock screening and cleaning, bleach plant, and bleach stock screening and cleaning.

Item is an aerial photograph of log rafts, log booms, and a mill.

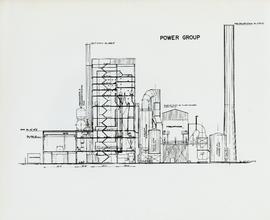

Item is a labeled diagram of the power group at a mill.

Item is a map that distinguishes the regions covered by Tree Farm Licence No. 1 granted to Columbia Cellulose and Three Farm Licence No. 40 granted to Skeena Kraft. Major locations indicated in this map include: Prince Rupert, Terrace, Hazelton, Smithers, Kitimat, Skeena River, and Nass River. Railway routes are also shown.

Item is a photograph of a raft of logs being guided through a log boom by a boom boat and a man or log driver with a pike pole standing on a nearby log raft.

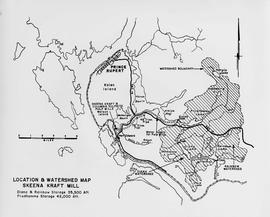

Item is a map showing the watersheds of Diana Lake, Rainbow Lake and Prudhomme Lake.

Attached description: A railway spur built for materials handling during construction was designed to be converted after startup into a shed for handling railway loading of Skeena Kraft pulp. A forklift is shown loading a railcar with prime Skeena bleached kraft pulp in bales.

Item is a picture of a filly loaded logging truck with two trailers stopped on a dirt road. A van from "Commins Diesel Vancouver Island Ltd. Nanaimo" is parked in front of the truck.

Attached description: The world's largest airborne Flakt drier, manufactured by SF Products of Canada, is in operation in the 750 t/d Skeena Kraft mill. The pulp sheet, 228 inches wide, makes 23 passes through the drier in just over eleven minutes. The picture shows the huge laminated beam used in this section of the mill. The building is bright and well-ventilated, providing excellent working conditions for the operating and maintenance personnel. In the foreground, the cutter-layboy is in operation.

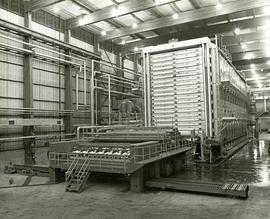

Attached description: Five huge IMPCO washers are shown in this interior shot of the pulping group. The washers are situated parallel with the bleaching towers outside the building, matching the conventional five-stage bleaching sequence used. The picture is taken from a spacious centre isle which makes housekeeping duties and maintenance easy. Centered in the picture is ventilating equipment which keeps the operating floor at comfortable temperatures for operating personnel. Four of the washers are conventional conical valve washers; Washer No. 2 is an IMPCO CV (centre-valve) caustic washer.

Crews of sure-footed boom men in the Nass area, largely composed of Indigenous locals, work throughout the year on logging operations of Twinriver Timber Limited. Their homes are located near Nass River in the towns of Aiyansh, New Aiyansh, Greenville, and Canyon City.

Item is a diagram of the filter plant and lime kiln of the mill.

File consists of the "Feasibility Study of Nass River Valley Log Transport Systems," which includes:

- Present log transportation methods

- Factors affecting Nass Valley log transportation

- Recommended road improvement

- Recommended trucking methods and equipment

- Alternative transportation systems

- Comparison of system costs

- Cycle times and production estimates

- Estimated main-line trucking costs

- Alternative dumping sites

- Advantages of truck transport

- Other considerations

- Time schedule to carry out changes

- Alternative routes

- Appendices.

Attached description: Double trailers deliver log loads to dump at Clark Booming Grounds of Twinriver Timber Limited. Logs are bundled before dumping.

Item is a diagram of the digesters of the pulp mill.

File consists of:

- "Development Study - Northern Resources" by the Columbia Cellulose Company, Limited, September, 1963. This report includes: background information on the company and a contextual background of forestry in British Columbia; a description of resources and proposed facilities, which covers northern wood resources and requirements for future sulphite and sulphate mills; an economic study for new Kraft operations.

- 2 maps: one of British Columbia entitled "Status of Sustained-Yield Forestry Programme as at 31 December 1962" by the Department of Lands, Forests, and Water Resources; the other of British Columbia Forest Service Forest: Surveys and Inventory Division, Key Map Showing: Maps published on scale 1 inch to 2 miles and summary zones of the provincial forest inventory by the Department of Lands and Forests (1957).

Attached description: An extensive program of development was undertaken for the new Skeena Kraft mill water supply. Dams were constructed to improve storage in the several lakes supplying the water; these are primarily, Diana, Prudhomme and Rainbow. This picture shows the large dam constructed on Diana Lake. A 78-inch wood stave pipeline was built, and now supplements the 48-inch pipeline that served the existing sulphite mill. Enough water is transported to supply a city of more than 100,000 population.

Series consists of documents providing information on the Columbia Cellulose Company, Limited including its history, historical and geographical context, and plans for the future. These documents often include photographs, maps, and technical drawings of the mills. Series consists of Skeena Kraft press kit; Feasibility Study of Nass River Valley Log Transport Systems; A Summary History and Progress; Development Study: Northern resources; Columbia Cellulose Company, Limited.

Fonds consists of documents providing information on the Columbia Cellulose Company, Limited covering the period of 1959-1970. These documents detail the company’s history, historical and geographical context, and plans for the future. Files often include photographs, maps, and technical drawings of the mills.

Columbia Cellulose Company, LimitedFile consists of a 33 paged report on the history of the Columbia Cellulose Company, Limited as of August 20, 1959.

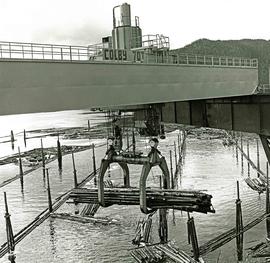

Attached description: The operator's cabin is visible behind the Colby 70-ton bridge crane grapples as it lifts a bundle of logs to the breakdown deck. In the background, a boomboat brings another bundle into position for pickup from the holding bay inside the pond formed by the dock.

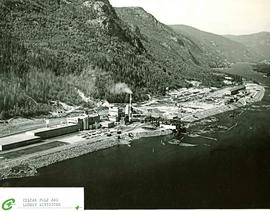

Item is an aerial photograph of mill by a waterway.

Item is an aerial photograph of mill by a waterway.

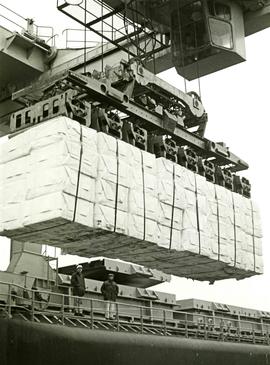

Attached description: Unitized bundles of eight strapped pulp bales weighing 16 tons are loaded into the ship's hold by specially designed over-running cranes.

Item is a map of British Columbia and is a key map showing: maps published on scale 1 inch to 2 miles and summary zones of the provincial forest inventory. Map includes index of post offices correct to October 22, 1956.

Attached description: The two black tanks in the foreground are blow tanks for the two Kamyr digesters which tower behind them. This picture, taken from ground level, shows graphically the 210-foot height of the digesters. Chip conveyors lead in from the right. Each digester is served by a separate conveying line, providing flexibility in the type of wood used, and also ensuring that operation of one digester can continue.

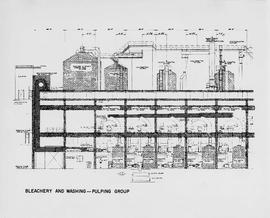

Item is a diagram of the bleachery and washing portion of the pulp mill.

Attached description: The thriving city of Prince Rupert is shown in this aerial picture. Prince Rupert has been enjoying a construction boom which includes the construction of the $80 million Skeena Kraft mill, hundreds of single-family homes, and hundreds of units in apartments, motels, and hotels. The construction of Skeena Kraft provided the stimulus for a population expansion to over 17,000. The Columbia Cellulose and Skeen a Kraft payrolls account for well over a third of the incomes of the city. Prince Rupert is, along with Terrace, the hub of a new economic region encompassing the Nass and Skeena valley regions.

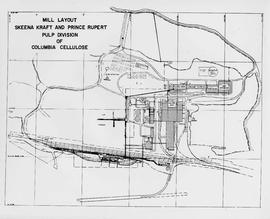

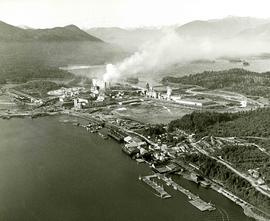

Attached description: Both the Columbia Cellulose Sulphite mill and the Skeena Kraft mill are shown in this aerial view. Woodroom No. 2 is shown at the left, and the main buildings of the sulphite mill in center. The right centre area of the picture shows the new 750 t/d Skeena Kraft mill. Skeena Kraft is the largest single-line pulp mill in operation in the world. In the foreground is the fishing village of Port Edward. The Integration of chip manufacturing and power plants provides the mills with common service facilities. Watson Island is approximately 11 miles from the city of Prince Rupert, which now has a population of about 17,000 people.

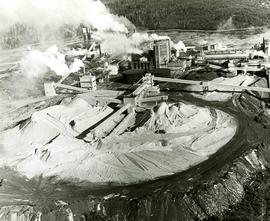

Attached description: This aerial view of the chip distribution system shows the network of enclosed conveyors which distribute different species of chips to individual piles. Reclaim-pits under these piles pick up chips for transporting to the two Kamyr continuous digesters. The building in the lower right of the picture is the main structure, housing the transfers and screening with the operators on the top floor. A blower system is used to carry chips from the existing Woodroom No. 1 to the piles. In the background, the sulphite and kraft pulping groups of Columbia Cellulose and Skeena Kraft are shown.

File consists of a document entitled "A Summary: History and Progress," which contains an overview of Columbia Cellulose Company's operations, ownership and financing, management staff, progress during 1968, three-year profit plan targets 1969-1971, and general information (magazine reprints, photographs, 1967 annual report, and 1968 interim reports).