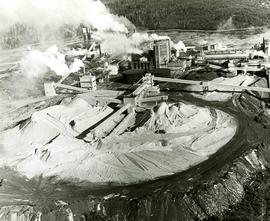

Attached description: This aerial view of the chip distribution system shows the network of enclosed conveyors which distribute different species of chips to individual piles. Reclaim-pits under these piles pick up chips for transporting to the two Kamyr continuous digesters. The building in the lower right of the picture is the main structure, housing the transfers and screening with the operators on the top floor. A blower system is used to carry chips from the existing Woodroom No. 1 to the piles. In the background, the sulphite and kraft pulping groups of Columbia Cellulose and Skeena Kraft are shown.

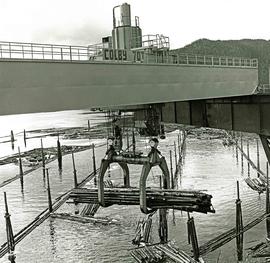

Attached description: The operator's cabin is visible behind the Colby 70-ton bridge crane grapples as it lifts a bundle of logs to the breakdown deck. In the background, a boomboat brings another bundle into position for pickup from the holding bay inside the pond formed by the dock.

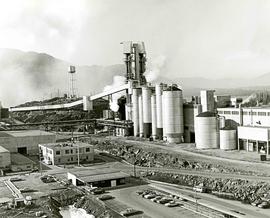

Attached description: The Skeena Kraft Group occupies the center of this picture showing the bleaching towers and the continuous Kamyr digesters. In the foreground is the Administration building, the Personnel and Safety building, and the employees' parking lot. The covered conveyor leading to the digesters carries chips. An emergency 1,000,000 water tower stands on the hill in the background.

Attached description: The two black tanks in the foreground are blow tanks for the two Kamyr digesters which tower behind them. This picture, taken from ground level, shows graphically the 210-foot height of the digesters. Chip conveyors lead in from the right. Each digester is served by a separate conveying line, providing flexibility in the type of wood used, and also ensuring that operation of one digester can continue.

Attached description: Five huge IMPCO washers are shown in this interior shot of the pulping group. The washers are situated parallel with the bleaching towers outside the building, matching the conventional five-stage bleaching sequence used. The picture is taken from a spacious centre isle which makes housekeeping duties and maintenance easy. Centered in the picture is ventilating equipment which keeps the operating floor at comfortable temperatures for operating personnel. Four of the washers are conventional conical valve washers; Washer No. 2 is an IMPCO CV (centre-valve) caustic washer.

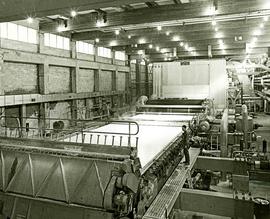

Attached description: This picture shows the 240-inch cantilevered fourdrinier operating in the Skeena Kraft mill. It includes a suction press in the first position and two grooved presses in the second and third positions. The fourdrinier has a 37-foot forming length and is equipped with 25 table rolls, seven suction boxes, a Potabelt and forming boards. It is also equipped with a 30-inch diameter dandy roll, wier shower, 50-inch diameter vacuum couch with a presser roll.

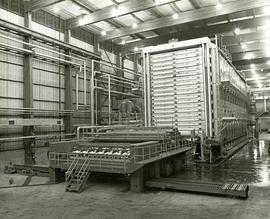

Attached description: The world's largest airborne Flakt drier, manufactured by SF Products of Canada, is in operation in the 750 t/d Skeena Kraft mill. The pulp sheet, 228 inches wide, makes 23 passes through the drier in just over eleven minutes. The picture shows the huge laminated beam used in this section of the mill. The building is bright and well-ventilated, providing excellent working conditions for the operating and maintenance personnel. In the foreground, the cutter-layboy is in operation.

Attached description: An extensive program of development was undertaken for the new Skeena Kraft mill water supply. Dams were constructed to improve storage in the several lakes supplying the water; these are primarily, Diana, Prudhomme and Rainbow. This picture shows the large dam constructed on Diana Lake. A 78-inch wood stave pipeline was built, and now supplements the 48-inch pipeline that served the existing sulphite mill. Enough water is transported to supply a city of more than 100,000 population.

Attached description: Workmen place last steel plates of Kamyr continuous digester - one of two which now feed the Skeena Kraft mill.

Attached description: In early stages of construction Skeena Kraft mill was a beehive of activity as carpenters, steel workers, welders and many other trades project to completion.

Attached description: A railway spur built for materials handling during construction was designed to be converted after startup into a shed for handling railway loading of Skeena Kraft pulp. A forklift is shown loading a railcar with prime Skeena bleached kraft pulp in bales.

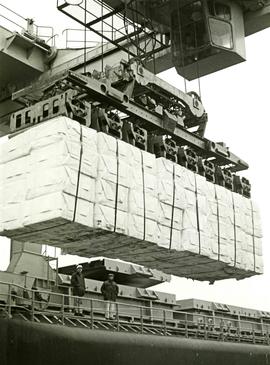

Attached description: Unitized bundles of eight strapped pulp bales weighing 16 tons are loaded into the ship's hold by specially designed over-running cranes.

Attached description: The thriving city of Prince Rupert is shown in this aerial picture. Prince Rupert has been enjoying a construction boom which includes the construction of the $80 million Skeena Kraft mill, hundreds of single-family homes, and hundreds of units in apartments, motels, and hotels. The construction of Skeena Kraft provided the stimulus for a population expansion to over 17,000. The Columbia Cellulose and Skeen a Kraft payrolls account for well over a third of the incomes of the city. Prince Rupert is, along with Terrace, the hub of a new economic region encompassing the Nass and Skeena valley regions.

Attached description: A mile-long shear boom on the Nass River is used to guide single logs into holding ponds where they await bundling, booming and towing to mills. Boom is cleared of debris daily by river crew.

Attached description: Double trailers deliver log loads to dump at Clark Booming Grounds of Twinriver Timber Limited. Logs are bundled before dumping.

Photograph depicts a snow covered cemetery with gravestones, tombstones, and monuments.

Slide depicts a man operating heavy equipment in a forest, likely at the Aleza Lake Experiment Station.

Slide depicts a heavily forested area with fallen logs, likely at the Aleza Lake Experiment Station.

Slide depicts a sawmill in operation, likely located in the Upper Fraser area, with a pile of burning wood products and a beehive burner.

Slide depicts a black bear eating garbage by wooden outbuildings, possibly at the Aleza Lake Experiment Station.

Slide depicts the original wooden BC Forest Service sign for the Aleza Lake Forest Experiment Station.

Slide depicts a detonation in an area of cleared ground in a forested area, likely the Aleza Lake Experiment Station. Work may have been undertaken for roadbuilding activities at the Experiment Station.

Slide depicts a cleared area in a forest, likely at the Aleza Lake Experiment Station.

Slide depicts a burning building at the Aleza Lake Experiment Station on the date it was shut down by the BC Forest Service.

Slide depicts a cleared area at the Aleza Lake Experiment Station with plant regeneration.

Slide depicts a view of what is possibly the Upper Fraser River.

Slide depicts the Ranger Station at the Aleza Lake Experiment Station.

Slide depicts cleared ground and felled trees in a forested area, likely at the Aleza Lake Experiment Station.

Slide depicts a bulldozer clearing ground, likely at the Aleza Lake Experiment Station.

File consists of a photograph commemorating the signing of the first Aleza Lake Research Forest Management Plan. Front row, left to right: Ken Pendergast, BC Forest Service Prince George District Manager; Harry Coates, BCFS Forest Research Technician (1957-1993); John Revel, BCFS Silviculture Forester (1960-1993). Back row, left to right: Mike [?], BCFS Prince George Silviculture Manager; Henry Benskin, BCFS Research Branch; Michael Jull, BCFS Research Silviculturist, Prince George Region; Dan Lousier, BCFS Prince George Region Research Section Head; Brian Harding, Northwood Pulp & Timber Ltd. Woodlands Manager.

Annotation on slide: "Summit Lake D4H highdrive"

Annotation on photograph verso: "D-4 tracked skidder at Start of B Road. 15/1/92. Summit Lake Selection Trial"

Annotation on photograph verso: D-4 tracked skidder at "Start of B Road. 15/1/92. Summit Lake Selection Trial"

Annotation on photograph verso: "D-4 tracked skidder. 15/1/92. Summit Lake Selection Trial"

Annotation on photograph verso: "D-4 tracked skidder. 15/1/92. Summit Lake Selection Trial"

Annotation on photograph verso: "South of plots 27, 21. 15/1/92. (Post-logging). Summit Lake Selection Trial"

Annotation on photograph verso: "View south of unit 27 Post-logging. 15/1/92. Summit Lake Selection Trial"

Annotation on photograph verso: "South of plot 27, N of 18, 20. 15/1/92. Post-logging. Summit Lake Selection Trial"

Annotation on photograph verso: "View from Jtn of A Road and Main Road to NE. Pre-logging. 15/1/92. Summit Lake Selection Trial"

Annotation on photograph verso: "View SE from Jtn of A Road and Main Road. Uncut stand on left; selection logging virtually complete in centre and right. 15/1/92. Summit Lake Selection Trial"

Annotation on photograph verso: "View SE from Jtn of A Road and Main Road. Uncut stand on left; selection logging virtually complete in centre and right. 15/1/92. Summit Lake Selection Trial"

Annotation on photograph verso: "D6 grapple skidder used for road development only. 27/12/91. Summit Lake Selection Trial"

Annotation on photograph verso: "Summit Lake Trial EP 1162, Winter 1991/1992"

Annotation on photograph verso: "July-Aug. 1991, View of Summit Lake EP 1162. Area from top of Teapot Mountain, looking east. Trial area is east of Crooked River, north of Caine Creek [Forest Service] Road, south of gravel pit (on right)".

Annotation on slide: "Summit Lake D4H highdrive"

Annotation on slide: "Summit Lake D4H highdrive skidder"

Annotation on slide: "Summit Lake D4H on skid road"

Annotation on slide: "Summit Lake D4H on skid road"

Annotation on slide: "Summit Lake M. Jull on skid road with advanced regen".

Annotation on slide: "Summit Lake, D4H on narrow skid road".